China Duct Fiber Optic Cable Manufacturer

We’re leading China-based manufacturer of duct fiber optic cables. Specializing in producing reliable and high-performance cables for underground telecommunication and broadband infrastructure. Offering a wide range of products to meet diverse project requirements.

Our Duct Fiber Optic Cables

Duct fiber optic cables are a popular choice, but the best option depends on your specific project and location. For instance, customers in the UK often prefer duct cables with steel tape armor and an LSHZ outer sheath. However, others might choose a non-metallic, armor-free cable.

To ensure you select the right cable for your needs, we recommend consulting with our experienced team.

Custom Duct Fiber Optic Cable

Our expert team designs and manufactures custom fiber optic cables specifically engineered to excel in the rigors of duct installations. From cable composition and armoring to length and termination options, we provide complete flexibility to meet your unique project requirements.

Whether you’re facing challenging terrain, harsh climates, or demanding data transmission needs, our custom duct fiber optic cables deliver exceptional performance.

Contact us to discuss your project and explore our comprehensive range of solutions.

Applications for Duct Fiber Optic Cable

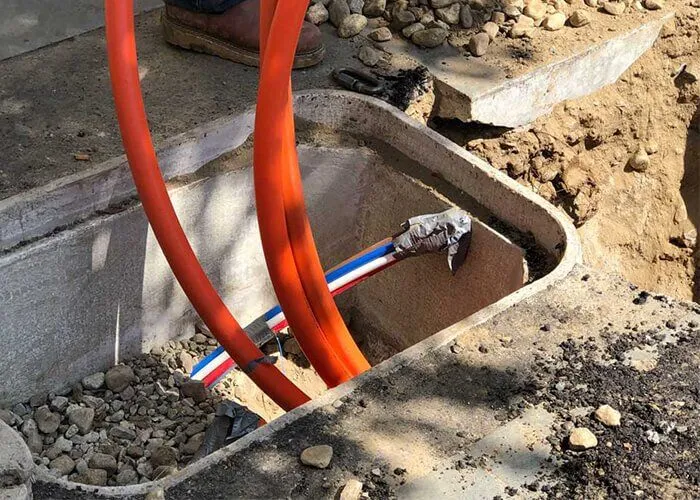

Duct fiber optic cables are typically buried underground. They are commonly used in large city networks, local area networks, and as main cables for delivering fiber internet directly to homes.

Metropolitan Areas

Access Network

FTTH Network

Duct Fiber Optic Cable: A Comprehensive Guide

1. What is Duct Fiber Optic Cable?

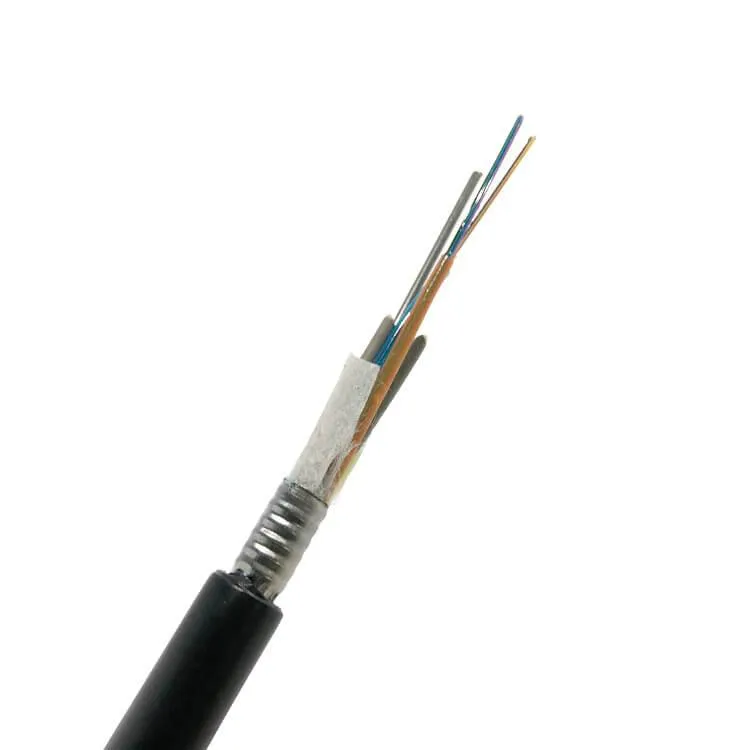

Duct fiber optic cable is a specialized type of optical cable designed for installation within pre-laid conduits or ducts. These ducts can be made of various materials such as concrete, PVC, or steel. The cable is constructed to withstand the physical stresses and environmental conditions encountered within these ducts, ensuring reliable and long-term performance.

2. How Can Duct Fiber Optic Cable Have Great Performance?

Duct fiber optic cable achieves exceptional performance through several key factors:

- Robust Construction: The cable is designed with sturdy outer jackets and protective layers to shield the optical fibers from external forces like crushing, bending, and tension.

- Water-Blocking Measures: Effective water-blocking materials and techniques are employed to prevent water ingress, which can degrade fiber performance.

- Low Attenuation: High-quality optical fibers with minimal signal loss contribute to efficient data transmission over long distances.

- Temperature Resistance: The cable is engineered to withstand a wide range of operating temperatures, ensuring reliable performance in diverse environments.

3. What are the Applications of Duct Fiber Optic Cable?

Duct fiber optic cable finds extensive applications across various industries:

- Telecommunications: For high-speed internet, data communication, and voice services.

- Cable Television: To deliver video content to subscribers.

- Enterprise Networks: For connecting multiple buildings and campuses.

- Government and Military: For secure communication and surveillance systems.

- Oil and Gas: For monitoring pipelines and remote installations.

4. What are the Advantages of Duct Fiber Optic Cable?

Duct fiber optic cable offers several advantages:

- High Bandwidth: Capable of transmitting vast amounts of data at incredible speeds.

- Long Distance Transmission: Supports long-distance communication without signal degradation.

- Immunity to Electromagnetic Interference (EMI): Ensures reliable data transmission in noisy environments.

- Security: Offers enhanced security compared to copper cables due to the difficulty of tapping into fiber optic signals.

- Durability: Designed to withstand harsh environmental conditions and physical stresses.

- Flexibility: Can be installed in various duct types and configurations.

5. What are the Types of Duct Fiber Optic Cable?

The choice of duct fiber optic cable depends on specific application requirements:

- Loose Tube Cable: Offers flexibility and ease of installation.

- Tight Buffer Cable: Provides higher density and smaller cable diameter.

- Central Loose Tube Cable: Combines the advantages of loose tube and tight buffer designs.

- Modular Cable: Offers flexibility in fiber count and cable diameter.

- Ribbon Cable: Provides high fiber density and efficient installation.

6. What are the Materials for Duct Fiber Optic Cable?

Duct fiber optic cables are typically constructed using the following materials:

- Optical Fiber: The core component for transmitting light signals.

- Buffer Coating: Protects the optical fiber from external damage.

- Strength Member: Provides mechanical strength to the cable.

- Water-Blocking Material: Prevents water ingress and protects the optical fibers.

- Jacket: Provides overall protection and identifies the cable type.

- Armor: Optional layer for added protection in harsh environments.

By understanding the characteristics and benefits of duct fiber optic cable, you can make informed decisions for your network infrastructure.