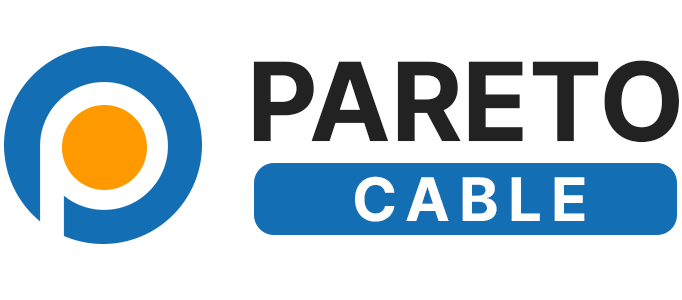

China Tight Buffer Fiber Optic Cable Manufacturer

We’re leading China-based manufacturer of tight buffer fiber optic cables. Specializing in high-performance solutions for telecommunications, data centers, and industrial applications. Our cables offer superior signal integrity, low attenuation, and exceptional durability. Benefit from our competitive pricing, customization options, and prompt delivery.

Our Tight Buffer Fiber Optic Cables

Tight buffer fiber cables are great for connecting and distributing light signals indoors. However, not all tight buffer cables are created equal. If you’re looking to purchase one, our expert team can help you find the perfect cable for your needs.

Custom Tight Buffer Fiber Optic Cable

Our custom tight buffer fiber optic cables offer unparalleled flexibility and precision for your specific network requirements. Engineered with meticulous attention to detail, these cables deliver superior signal integrity and durability in demanding environments.

Experience the difference of a truly customized tight buffer fiber optic cable solution. Contact us today to discuss your project needs.

Applications for Tight Buffer Fiber Optic Cable

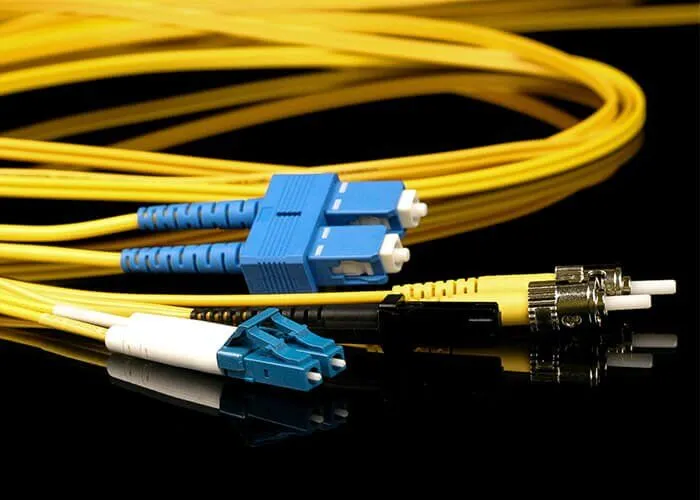

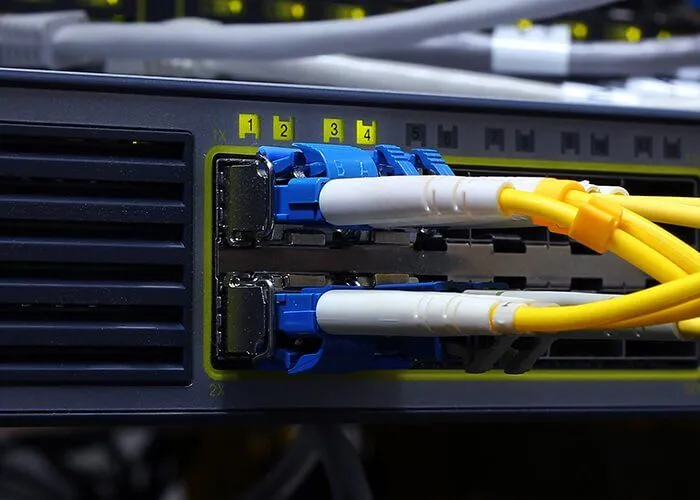

Tight buffer fiber optic cables are widely used indoors for various optical distribution applications. These cables are popular because of their excellent performance. They are commonly found in fiber patch cords, pigtails, and connections between devices. Additionally, tight buffer cables are used to distribute signals between different floors in buildings.

Fiber Patch Cord

Connecting Equipment

Indoor Optical Distribution

Tight Buffer Fiber Optic Cable: A Comprehensive Guide

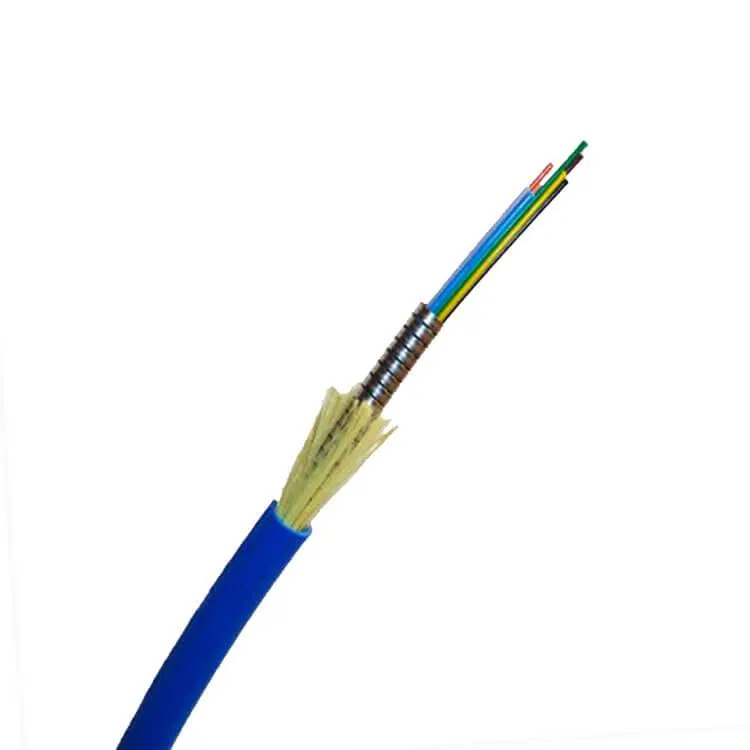

1. What is Tight Buffer Fiber Optic Cable?

Tight buffer fiber optic cable, as the name suggests, features a fiber core encased in a tight-fitting plastic buffer. This buffer provides essential protection against mechanical stress and environmental factors. Unlike loose tube cables, which offer more cushioning, tight buffer cables prioritize flexibility and ease of installation.

2. How Can Tight Buffer Fiber Optic Cable Have Great Performance?

Tight buffer fiber optic cables excel in performance due to several key factors:

- Minimal Bending Loss: The tight buffer ensures the fiber remains straight, reducing signal attenuation caused by bending.

- Fast Installation: The absence of gel or loose tubes simplifies the termination process, leading to quicker installations.

- Lightweight and Flexible: These cables are ideal for applications requiring flexibility and minimal space.

- Durability: The tight buffer offers solid protection against environmental factors and handling.

3. What are the Applications of Tight Buffer Fiber Optic Cable?

Tight buffer fiber optic cables find widespread use in various applications:

- Indoor cabling: Campus networks, data centers, and office buildings.

- FTTH (Fiber to the Home): Due to their flexibility and ease of installation.

- Industrial environments: Where durability and resistance to harsh conditions are required.

- Pigtails and patch cords: For connecting fiber optic devices.

4. What are the Advantages of Tight Buffer Fiber Optic Cable?

- High flexibility: Ideal for tight spaces and bending requirements.

- Easy installation: Quick termination and lower labor costs.

- Lightweight: Reduces installation effort.

- Cost-effective: Generally more economical than loose tube cables.

- Excellent performance: Low attenuation and high bandwidth.

5. What are the Types of Tight Buffer Fiber Optic Cable?

Tight buffer fiber optic cables can be categorized based on different parameters:

- Fiber type: Single-mode or multimode.

- Core count: Varies depending on application requirements.

- Jacket material: PVC, LSZH (Low Smoke Zero Halogen), or other materials based on environmental conditions.

- Armor: Some cables may include additional layers of protection, such as aluminum or steel tape armor.

6. What are the Materials for Tight Buffer Fiber Optic Cable?

The primary materials used in tight buffer fiber optic cables include:

- Fiber core: Made of high-purity silica glass.

- Buffer coating: Typically PVC or acrylate.

- Jacket: PVC, LSZH, or other materials depending on the application.

- Strength members: Aramid yarn or steel wire for added tensile strength.

- Armor: Aluminum or steel tape for additional protection in harsh environments.

By understanding the characteristics and advantages of tight buffer fiber optic cable, you can make informed decisions for your cabling projects.