China Air Blown Fiber Optic Cable Manufacturer

We’re Manufacturer of Air Blown Fiber Optic Cables. With state-of-the-art facilities in China, we produce high-quality air blown fiber optic cables designed for rapid deployment in various applications. Our commitment to excellence ensures optimal network performance and customer satisfaction.

Our Air Blown Fiber Optic Cables

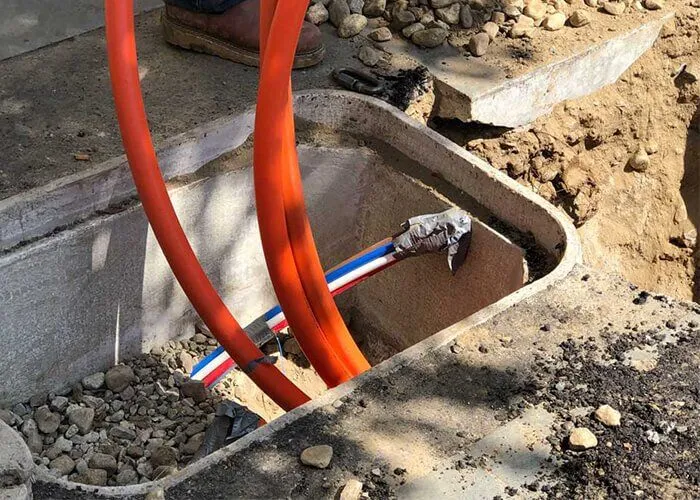

Air-blown fiber optic cable is a special type of cable that can be installed in tiny tubes without digging up the ground. This is possible because it’s designed to be blown into place using air pressure. Additionally, it can be inserted into existing fiber optic pipelines, saving time and resources while allowing for quick network expansions.

Custom Air Blown Fiber Optic Cable

Our custom air blown fiber optic cables offer a flexible and cost-effective approach to building high-performance networks. By leveraging advanced air blowing technology, we deliver precisely engineered cables to meet your specific requirements.

Whether you need solutions for FTTH, data centers, or enterprise networks, our expert team will collaborate with you to develop the ideal air blown fiber optic cable solution.

Applications for Air Blown Fiber Optic Cable

Air-blown micro fiber optic cable is commonly used to connect the central part of a fiber-to-the-home (FTTH) network to individual homes or businesses. This type of cable is installed by blowing it through a tube using compressed air. It’s also suitable for larger networks, like those used between cities or within a city.

Access Network

FTTH Network

Metropolitan Areas

Air Blown Fiber Optic Cable: A Comprehensive Overview

1. What is Air Blown Fiber Optic Cable?

Air blown fiber optic cable, often abbreviated as ABF, is a revolutionary fiber optic cable installation method that involves blowing individual fibers or bundles of fibers into a pre-installed microduct using compressed air. Unlike traditional cable pulling, where the entire cable is pulled through conduits, ABF offers a faster, more efficient, and less disruptive installation process.

2. How Can Air Blown Fiber Optic Cable Have Great Performance?

Air blown fiber optic cable exhibits superior performance due to several factors:

- Reduced Fiber Stress: The blowing process eliminates the tensile stress on the fiber, which is a common cause of attenuation and signal degradation in traditional installation methods.

- Minimal Splice Points: ABF allows for longer fiber runs with fewer splice points, enhancing signal quality and reducing signal loss.

- Flexibility and Light Weight: The individual fibers or small bundles are highly flexible and lightweight, making them easier to install and handle.

- Rapid Deployment: The air blowing method significantly accelerates the installation process compared to traditional cable pulling.

3. What are the Applications of Air Blown Fiber Optic Cable?

Air blown fiber optic cable finds applications in a wide range of sectors:

- Telecommunications: For deploying high-speed broadband networks, FTTH (Fiber to the Home) initiatives, and backbone infrastructure.

- Data Centers: For interconnecting servers, storage devices, and network equipment.

- Enterprise Networks: For campus networks, building-to-building connections, and indoor cabling.

- Smart Grids: For monitoring and controlling power distribution networks.

- Industrial Automation: For connecting sensors, actuators, and control systems in factories and industrial facilities.

4. What are the Advantages of Air Blown Fiber Optic Cable?

Air blown fiber optic cable offers numerous advantages:

- Faster Installation: The air blowing method is significantly faster than traditional cable pulling.

- Lower Installation Costs: Reduced labor and equipment requirements contribute to lower installation costs.

- Easy Network Expansion: Additional fibers can be easily blown into existing microducts as needed.

- Reduced Service Outages: Minimized disruptions during installation and maintenance.

- Improved Network Reliability: Reduced fiber stress and fewer splice points lead to enhanced network performance.

- Environmentally Friendly: Less material used compared to traditional cable installation.

5. What are the Types of Air Blown Fiber Optic Cable?

There are primarily two types of air blown fiber optic cables:

- Loose Tube Air Blown Fiber Cable: Individual fibers are housed in loose tubes within the microduct.

- Tight Buffer Air Blown Fiber Cable: Each fiber is individually coated with a tight buffer before being blown into the microduct.

6. What are the Materials for Air Blown Fiber Optic Cable?

The materials used in air blown fiber optic cables include:

- Fiber: High-quality optical fiber for efficient light transmission.

- Buffer Coating: Protects the fiber from external influences.

- Loose Tube (if applicable): Protects the fibers within the cable.

- Central Strength Member: Provides structural support to the cable.

- Microduct: The tube through which the fibers are blown.

- Jacket: Provides overall protection for the cable.

Air blown fiber optic cable technology is rapidly gaining popularity due to its numerous benefits and versatility. Its ability to deliver high-speed data transmission, coupled with efficient installation and scalability, makes it a preferred choice for various network applications.