China Direct Buried Fiber Optic Cable Manufacturer

Your trusted partner for direct buried fiber optic cable solutions. We are a China-based manufacturer committed to providing high-quality, cost-effective cables for various applications. Our cables are designed to withstand harsh underground environments while ensuring optimal signal transmission.

Our Direct Buried Fiber Optic Cables

Pareto Cable’s Direct Buried Fiber Optic Cable offers a robust and cost-efficient solution for your communication needs. This cable features a strong outer layer of steel tape or wire, providing exceptional resistance against mechanical damage and soil erosion. This allows for direct burial in the ground, eliminating the need for expensive conduit systems or aerial installations.

Standard Types

Direct Buried Fiber Optic Cable Specifications

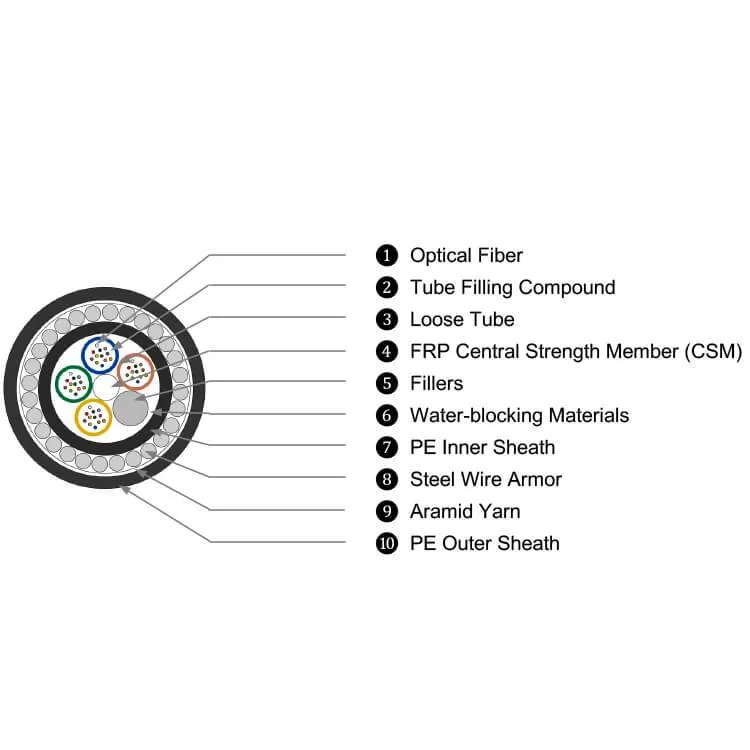

Our fiber optic units are engineered for exceptional durability with robust steel tape armoring and a double-layer sheath, making them ideally suited for direct burial installation. This protective design safeguards the fiber optic cables from external damage, ensuring reliable performance and longevity even in harsh underground conditions.

Features

- Quick and simple installation

- Superior mechanical and temperature resistance

- Durable and adaptable for direct burial

- Reliable APL moisture protection

- Advanced PSP moisture barrier technology

- Impenetrable water barrier for underground use

Applications

Long-distance communication and inter-office communication network

Direct Burial Fiber Optic Cable Solutions

Our direct burial fiber optic cables are engineered to withstand the harshest underground environments, providing unparalleled performance and longevity. Whether you’re expanding your network or building new infrastructure, we offer custom solutions to meet your specific needs.

Trust us for your direct burial fiber optic cable needs. Contact us today for a free consultation.

Direct Buried Fiber Optic Cable: A Comprehensive Guide

1. What is Direct Buried Fiber Optic Cable?

Direct buried fiber optic cable is a specialized type of cable designed for direct installation into the ground without the need for conduits or ducts. It’s constructed with robust materials and protective layers to withstand harsh underground conditions, including moisture, temperature fluctuations, and potential physical damage.

2. How Can Tight Buffer Fiber Have Great Performance?

Tight buffer fiber is a key component in direct buried cables that contributes to their excellent performance. This type of fiber has a protective coating applied directly to the glass core, providing immediate protection. Key benefits of tight buffer fiber include:

- Improved strength: The tight buffer acts as a physical barrier, protecting the fiber from micro-bending and other stresses.

- Smaller cable diameter: This allows for easier installation and reduces the risk of damage during the burying process.

- Consistent performance: Tight buffer fiber offers stable attenuation and dispersion characteristics, ensuring reliable signal transmission.

3. What are the Applications of Direct Buried Fiber Optic Cable?

Direct buried fiber optic cables find widespread applications in various sectors due to their durability and reliability:

- Telecommunications: For long-haul and metropolitan networks, providing high-speed data transmission.

- Cable TV: Delivering video content to subscribers.

- Enterprise networks: Connecting multiple buildings or campuses.

- Oil and gas industry: Monitoring pipelines and remote facilities.

- Smart grid applications: Enabling communication between power grid components.

4. What are the Advantages of Direct Buried Fiber Optic Cable?

Direct buried fiber optic cables offer several advantages:

- Cost-effective: Eliminates the need for conduit or duct infrastructure, reducing installation costs.

- Reliable: Designed to withstand harsh underground environments, ensuring long-term performance.

- Secure: Less susceptible to vandalism or theft compared to aerial cables.

- Flexible: Can be installed in various terrains and conditions.

- High bandwidth: Supports large amounts of data transmission.

5. What are the Types of Direct Buried Fiber Optic Cable?

There are several types of direct buried fiber optic cables, each designed for specific applications and environments:

- Single-mode fiber: Used for long-distance transmission and high-speed data applications.

- Multimode fiber: Suitable for shorter distances and lower data rates.

- Loose tube fiber: Offers additional protection for the fibers within the cable.

- Tight buffer fiber: Provides immediate protection for the fiber core.

- Armored cable: Incorporates metallic layers for added protection against rodents and physical damage.

6. What are the Materials for Direct Buried Fiber Optic Cable?

Direct buried fiber optic cables are constructed using a combination of materials to ensure durability and performance:

- Fiber core: Made of high-purity silica glass.

- Buffer coating: Protects the fiber core from moisture and mechanical stress.

- Strength member: Provides structural support to the cable.

- Water-blocking material: Prevents water ingress into the cable.

- Jacket: Outer layer that protects the cable from environmental factors.

- Armor: Optional metallic layer for added protection.

By understanding the characteristics and benefits of direct buried fiber optic cables, you can make informed decisions for your network infrastructure.